|

|

|

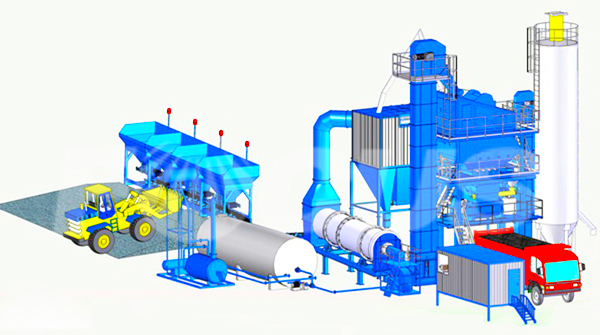

| Cold Aggregate Batcher | Drying Drum | Burner |

|

|

|

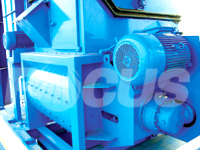

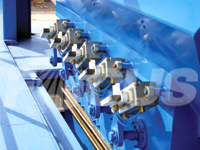

| Weighing System | Mixer | Imported double stroke cylinder with stone bucket door |

|

|

|

| Vibrating screen | Continuous localizer of hot aggregate container | Dust Collector |

|

|

|

| Asphalt Supply System | Computer control system | Control room |

| Style | LB500 | LB750 | LB1000 | LB1500 | LB2000 | LB2500 | LB3000 | LB4000 | |

| Rated Working capacity | 40t/h | 60t/h | 80t/h | 120t/h | 160t/h | 200t/h | 240t/h | 320t/h | |

| Cold Feed Bin | 4bin×6m3 | 4bin×6m3 | 4bin×9m3 | 4bin×9m3 | 5bin×11m3 | 5bin×11m3 | 5bin×11m3 | 5bin×11m3 | |

| Dryer Drum | 1.1m×4.2m | 1.3m×5m | 1.5m×6m | 1.8m×7m | 2.2m×8m | 2.35m×9m | 2.5m×10m | 2.8m×11m | |

| Bag Filter | CNM156 | CNM240 | CNM357 | CNM476 | CNM654 | CNM832 | CNM1012 | CNM1308 | |

| Emission Standard | 50mg/nm3 | 50mg/nm3 | 50mg/nm3 | 50mg/nm3 | 50mg/nm3 | 50mg/nm3 | 50mg/nm3 | 50mg/nm3 | |

| Screen Section | 4 Layers | 4 Layers | 4 Layers | 4 Layers | 5 Layers | 5 Layers | 5 Layers | 5 Layers | |

| Hot Bin | 12t | 12t | 26t | 26t | 40t | 40t | 80t | 100t | |

| Mixer Capacity | 500kg | 750kg | 1000kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg | |

| Mixing Cycle | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | |

| Filter Silo Capacity | 30t | 30t | 26+36t | 26+36t | 30+43t | 30+43t | 50+35t | 60+35t | |

| Bitumen Tanks Capacity | 30000L | 30000L | 50000L | 50000L | 2x50000L | 2x50000L | 3x50000L | 4x50000L | |

| Oil Heater |

200,000 kcal/h |

200,000 kcal/h |

300,000 kcal/h |

300,000 kcal/h |

500,000 kcal/h |

500,000 kcal/h |

800,000 kcal/h |

1,000,000 kcal/h |

|

| Mixer Material Silo | 50t | 50t | 90t | 90t | 110t | 110t | 200t | 200t | |

| Control System | Manual/Semi-auto/automatic | ||||||||

| Weighing Accuracy | Aggregate | ≤±0.4% | ≤±0.4% | ≤±0.4% | ≤±0.4% | ≤±0.4% | ≤±0.4% | ≤±0.4% | ≤±0.4% |

| Filter | ≤±0.3% | ≤±0.3% | ≤±0.3% | ≤±0.3% | ≤±0.3% | ≤±0.3% | ≤±0.3% | ≤±0.3% | |

| Bitumen | ≤±0.2% | ≤±0.2% | ≤±0.2% | ≤±0.2% | ≤±0.2% | ≤±0.2% | ≤±0.2% | ≤±0.2% | |

|

Total installed Power |

190kw | 210kw | 230kw | 320kw | 400kw | 530kw | 720kw | 820kw | |